8 juli 2021

Kamp C, the Westerlo-based provincial Centre for Sustainability and Innovation in Construction, recently started to build ‘t Centrum on its site at Westerlo. This innovative building combines various principles of sustainable construction to create the first circular office building in Belgium. An innovative learning process which the entire construction industry can draw on for inspiration.

Circularity and sustainability as cornerstones

The principles of the circular economy are paramount in circular construction. The idea is that materials are reused and recycled as much as possible while enabling the highest possible value retention of these resources. In this context, the concrete foundations are designed and dimensioned in such a way that they can be easily dismantled at end-of-life. The dimensions are standardised and can therefore be easily re-used in a new construction project in the future. While this means the foundation is circular, it is not necessarily sustainable. Traditional concrete contains a lot of cement, a raw material that is responsible for 8% of global CO2 emissions every year. The client therefore chose sustainable concrete mixtures, that were developed as part of the URBCON project, to increase the sustainability of the concrete used.

URBCON reduces the use of primary materials and CO2 emissions

Concrete is by far the most widely used building material in the world. The flipside of the coin is that it has a tremendous impact on our ecosystem. The cement industry in particular produces more than 4 billion tons of cementitious materials annually, responsible for more than 3 billion tons of CO2. In addition, tens of billions of tons of natural rocks and deposits are also excavated each year for use as sand or aggregate. The URBCON project, which received EU funding from the Interreg North-West Europe Programme, combines cutting-edge knowledge and expertise in sustainable concrete to tackle these issues. URBCON optimises the use of industrial by-products such as metallurgical slag or combustion ashes for the production of circular, sustainable and high-quality concrete.

From a small block in the lab to 55 m³ of foundation blocks in the ground

Under the leadership of ResourceFull and with the support of Ghent University, a test programme was set up for the development of a suitable concrete mixture for the foundations of 't Centrum with the minimum possible environmental footprint. The research started with the development of sustainable binders based on industrial waste streams.

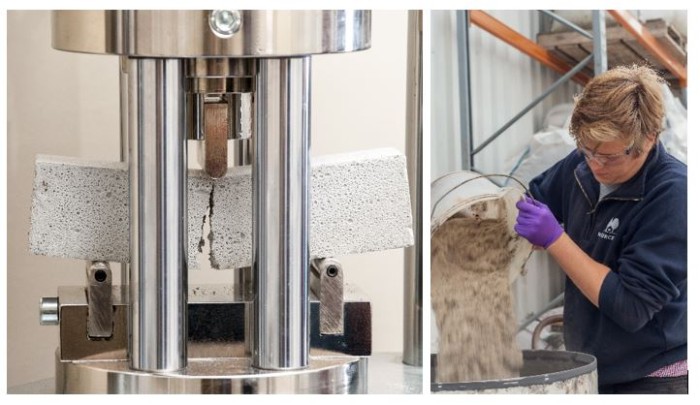

Traditional cement reacts with water, after which it cures and becomes stronger. Water alone is not sufficient to initiate the reaction of these industrial residual streams. You need to add chemical activators for this. That is why we worked hard in the lab to develop the right combination of raw materials and chemical activators. At the mortar level, properties such as tensile and compressive strength, flow and shrinkage were examined. In the concrete labs, the mixtures were scaled up based on the material and concrete properties of the intended application. The granular skeleton was optimised with a packing model that was developed in-house on the basis of the available sands and granulates at the manufacturer.

Based on tests with fresh concrete (flow, flow stability, curing time), cured samples (compressive strength, shrinkage, density, elastic modulus) and durability (freeze-thaw, resistance to carbonation, chloride penetration), equivalence was demonstrated with the two conventional blends, namely (1) C20/25 EE2 S5 and (2) C30/37 EE3 ZVB.

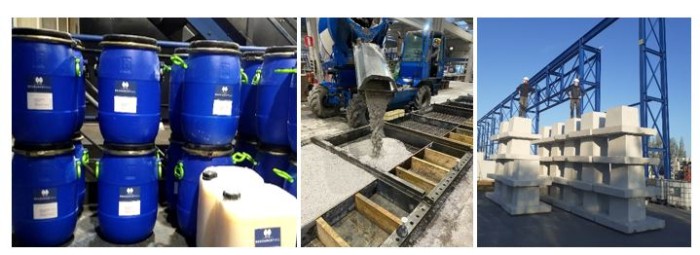

The foundation blocks were produced at Willy Naessens Construct in Oudenaarde. As the raw materials were already available in the silo, the implementation of the developed eco-binders was limited to digitally adjusting the mixing ratios and manually dosing the ResourceFull activators (15 – 40 kg/m³). The mixtures had a flow stability of 60 minutes, which is more than sufficient in a prefab production environment. After a final quality check, all the foundation elements were approved and successfully installed by Beneens in Westerlo. An additional 6 m³ of fresh eco-concrete was delivered from ready-mix concrete plant J. Janssens & Zonen in St.-Lenaarts, adding the final touch. By using the URBCON concrete composition in these foundation elements, 22,500 kilos of secondary materials were used and 13,000 kg less CO2 emitted, compared with conventional foundations.

With thanks to: Willy Naessens Construct, J. Janssens & Zonen, Beneens, ResourceFull and Ghent University.

Technical questions: mail wouter.crijns@resourcefull.eu

More information about ’t Centrum: https://www.kampc.be/tcentrum/circulair-bouwen-t-centrum

More information about URBCON: https://www.kampc.be/duurzaam/projecten/urbcon

Cover photo: foundations of 't Centrum made from URBCON concrete

Photo 1: Figure 1: Left: strength test on mortar beam (4x4x16cm³); Right: scaling up of the concrete mixtures

Photo 2: Figure 2: Left: ResourceFull's activators and additives; Centre: production of the foundation elements; Right: Cementless foundation elements