22 oktober 2021

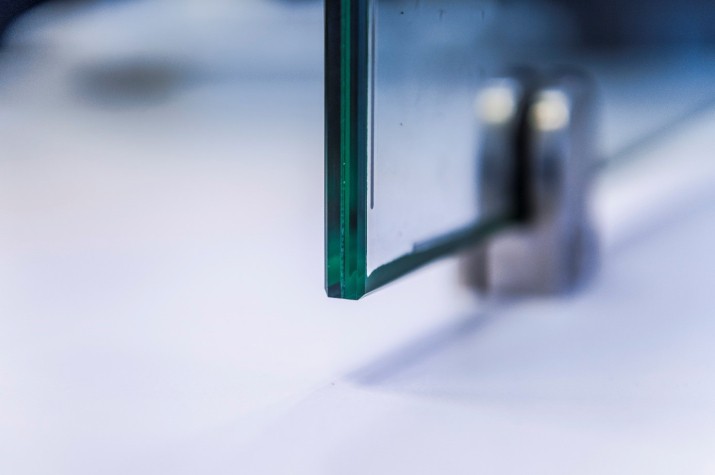

Part of the glazing of ‘t Centrum consists of vacuum insulating glazing. Equal to triple glazing when it comes to performance, it has the slim profile of single glazing, however. We spoke with Stefan Lips, Sales Director at FINEO Europe.

have long been looking for a way to sustainably produce vacuum insulating glazing. FINEO was developed by AGC Glass. Our parent company has already developed several techniques, similar to the techniques of the first types of vacuum insulated glazing that are still on the market today. However, we felt that if we wanted to bring a product to market, it also had to meet all the current challenges, with a clear focus on sustainability, aesthetics and circularity. The first generations of vacuum insulating glazing have a port on each pane for evacuating the internal volume with in-vacuum metal sealing of the edges. Our glazing is different in two respects. It no longer has a visible evacuation port. The edge seals are produced in such a way that once the pane is sealed it will remain sealed for a very long time. The panes are sealed with a glass paste, making it easier to recycle the glazing.”

2. Good thermal performance

Stefan Lips: “Essentially vacuum insulating glazing can be compared with the triple glazing that’s available on the market today as it has the same Ug value. The Ug value is the heat transfer coefficient. The lower this value, the better the thermal performance. Vacuum insulating glass has a Ug of 0.7. In other words: in terms of insulation performance, the glazing at ‘t Centrum is comparable to the currently available types of triple glazing. Obviously, there are other differences.

- Our glazing is lighter as we use one glass pane/coating less to achieve the same Ug value.

- AGC offers a 15-year warranty on FINEO glazing, meaning five years more than is legally required. Simulation models indicate that the connection can remain airtight for up to 60 years.

- By having one less glass pane/coating, you get much more light and free solar heat.

- In addition to providing thermal insulation, this type of glazing also provides excellent acoustic insulation.

- And it’s also highly recyclable.”

3. Less CO2 in production

Stefan Lips: “In terms of energy performance, the vacuum insulating glazing in 't Centrum scores 36% better than the legally required standard. It has the same U value as triple glazing, but we use one pane less when producing our glazing, which means that we emit much less CO2 right from the start. Although we use 30% less material, we still achieve a better performance (in the long run) with this glazing because we expect the U value to remain the same for 60 years. In effect this is an excellent example of dematerialisation: doing more with less.”

4. Spacers between the panes

Stefan Lips: “We call these spacers pillars in the industry. In vacuum technology you need spacers, otherwise the glass panes will stick together. While these are already barely visible, they will become completely invisible in the long term.”

5. Minimal price difference

Stefan Lips: “Compared with triple glazing, our glazing is slightly more expensive, as is the case with all new technologies. However, you need to take other factors into account. Our glazing offers better thermal performance, the window sections are smaller and you need fewer installers because of the lower weight. Meaning you save more money in the long run.”

Further information: www.fineoglass.eu

Photo: vacuum glazing at ’t Centrum - copyright FINEO/AGC